First Xwatch system fitted to JCB Pothole Pro for Balfour Beatty in Lincolnshire

Louise Carney

·

2 minute read

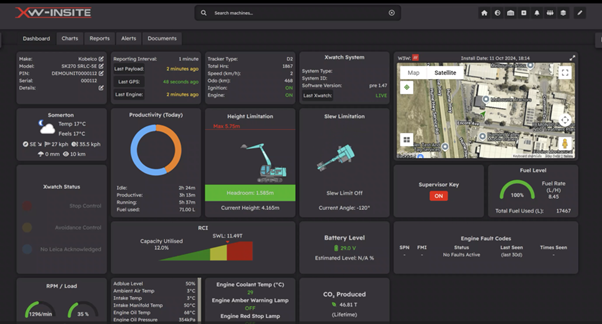

A JCB Pothole Pro working for Lincolnshire County Council has become the first of its kind to be fitted with an Xwatch safety system, marking a new step in protecting both operators and the public during live highway repairs.

A JCB Pothole Pro in service with Balfour Beatty for Lincolnshire County Council has become the first of its kind to be fitted with an Xwatch XW1 height restrictor system, bringing an extra layer of protection to one of the most innovative road repair machines on the network.

Installed by Xwatch engineer Tom DaCosta, the system has been fitted to a JCB Pothole Pro built on the chassis of the JCB Hydradig 110W wheeled excavator. While the Hydradig platform is already well known for its stability, visibility and compact working footprint, the Pothole Pro takes the concept further by combining cutting, cropping and cleaning into a single, purpose-built road repair solution.

With dedicated attachments including a planer, cropping tool and sweeper collector, the Pothole Pro allows crews to prepare a defect in one continuous operation. It reduces time on site, limits traffic disruption and improves consistency of repair – all while working in tight, live highway environments.

That working environment is exactly where the Xwatch XW1 system comes into its own.

The XW1 provides a programmable height limit, preventing the machine from exceeding a safe working envelope when operating near overhead hazards such as street lighting, signage, gantries and low structures. For a machine designed to work inches from live traffic, pavements and public space, that extra safeguard is significant.

For Balfour Beatty and Lincolnshire County Council, the fitment reflects a clear focus on risk reduction and operator confidence. The Pothole Pro is often deployed in urban and roadside settings where space is restricted and hazards are constant. The addition of Xwatch ensures that even in pressured, fast-moving environments, the machine remains within safe parameters.

For Xwatch Safety Solutions, it marks a first.

“This is the first Pothole Pro we’ve fitted, and it’s a great example of how safety technology can be seamlessly integrated into highly specialised machines,” said Tom DaCosta. “The Hydradig platform is already a strong base, and the Pothole Pro adds another layer of capability. With XW1 in place, the operator has that extra reassurance when working close to the public and infrastructure.”

Jemma Dycer Hopkins, Sales and Operations Manager at Xwatch Safety Solutions, added:

“Machines like the Pothole Pro are changing how highway work is done – faster, cleaner and with far less disruption. But they’re also working right in the middle of live environments, with the public just feet away. Adding Xwatch to this first machine is about giving the operator that extra layer of protection and confidence, and giving Balfour Beatty and Lincolnshire County Council reassurance that safety is built into every part of the job. It’s exactly where this kind of technology belongs.”

The installation also shows how Xwatch systems can extend beyond traditional excavator applications, supporting new machine types and emerging use cases across the sector. As local authorities and contractors look for quicker, smarter and safer ways to maintain the road network, machines like the Pothole Pro are becoming an increasingly familiar sight.

Now, with Xwatch on board, they are safer too.